In the modern construction market of the United States, no sector demands more accuracy, foresight, and technical expertise than industrial construction. From power plants and refineries to large-scale manufacturing facilities, every project comes with enormous budgets, strict timelines, and highly complex systems. In this environment, Construction Estimating Services for Precise Project Planning act as the backbone of project success, ensuring contractors and owners know exactly what resources, labor, and costs will be required before breaking ground.

Among these specialized services, Industrial Estimating Services stand out as one of the most critical disciplines. Industrial projects are not like residential homes or small commercial spaces; they involve multiple trades, advanced technologies, and significant safety requirements. Without a reliable estimate, even the most experienced contractors can face financial losses or schedule breakdowns.

Why Industrial Estimation Requires a Different Approach

Industrial estimating services in the USA are unique because they must capture the true scale of heavy infrastructure. A heavy industrial estimator USA does more than measure steel, concrete, and equipment. They must also account for plant operations, shutdown schedules, specialized labor productivity, and the integration of mechanical, electrical, and process systems.

For example, while a residential estimate may focus on framing, finishes, and standard utilities, an industrial construction estimating service must calculate costs for large piping systems, high-voltage electrical installations, specialized foundations, and compliance with OSHA safety standards. The margin for error is minimal. A small miscalculation in the length of pipe or power cabling could translate into hundreds of thousands of dollars in overruns.

This is why project owners, developers, and EPC contractors across the U.S. turn to industrial estimators who combine field knowledge with advanced digital tools, delivering a clear roadmap that protects budgets and timelines.

The Scope of Industrial Estimating Services

Industrial estimating covers a wide range of project types and requirements. Each category brings its own challenges and requires dedicated expertise.

Manufacturing Facility Estimates – Factories and production plants demand precise planning for structural steel, HVAC systems, fire suppression, and material handling equipment. Estimators must break down costs for each phase of the build, from site grading and foundations to equipment installation and commissioning.

Electrical Estimating for Industrial Buildings – Power distribution in industrial projects is complex, often involving high-voltage systems, transformers, and backup power solutions. Estimators must calculate not only the quantity of cable and conduits but also labor hours for specialized electricians.

Industrial MEP Estimating Services – Mechanical, electrical, and plumbing systems in industrial construction often interact with production machinery and safety systems. Estimators prepare detailed breakdowns of ductwork, piping, controls, and process utilities to ensure that costs are accurate and nothing is overlooked.

Industrial Shutdown Project Estimation – Many facilities, such as refineries or chemical plants, must shut down for maintenance and upgrades. These projects are high-pressure because every hour of downtime costs owners revenue. A shutdown estimator must prepare extremely detailed schedules, labor requirements, and material quantities to minimize delays.

By addressing these areas, industrial construction estimating services allow contractors to deliver accurate bids and project managers to maintain full financial control throughout the life of the project.

Supporting Bids and Tenders with Reliable Numbers

Winning an industrial project often depends on the strength of the bid. A industrial bid preparation service ensures that contractors submit proposals backed by data-driven estimates. Every component, from raw materials to subcontractor packages, must be accounted for.

In competitive U.S. tender environments, industrial tender and bid estimating services are indispensable. They prevent underpricing, which can destroy profitability, and overpricing, which can make a bid uncompetitive. With accurate estimates in hand, contractors can approach owners with confidence, knowing they are offering both value and reliability.

The Role of Technology and Expertise

Industrial projects demand more than just software calculations; they require experienced judgment. Tools such as PlanSwift, Bluebeam Revu, and RSMeans provide digital accuracy, but the human expertise of an industrial estimator makes the results trustworthy.

For instance, while software can generate a piping quantity takeoff, only an experienced estimator understands how plant layout, safety clearances, and installation methods affect labor productivity. In this sense, technology provides speed and precision, but expertise ensures realism and constructability.

This balance of digital and practical knowledge allows U.S.-based industrial estimating firms to deliver results that align with both field conditions and financial planning.

Challenges in Industrial Projects

Every industrial project presents unique challenges that highlight the importance of professional estimating. The complexity of trades, the scale of materials, and the safety-critical nature of systems leave no room for approximation.

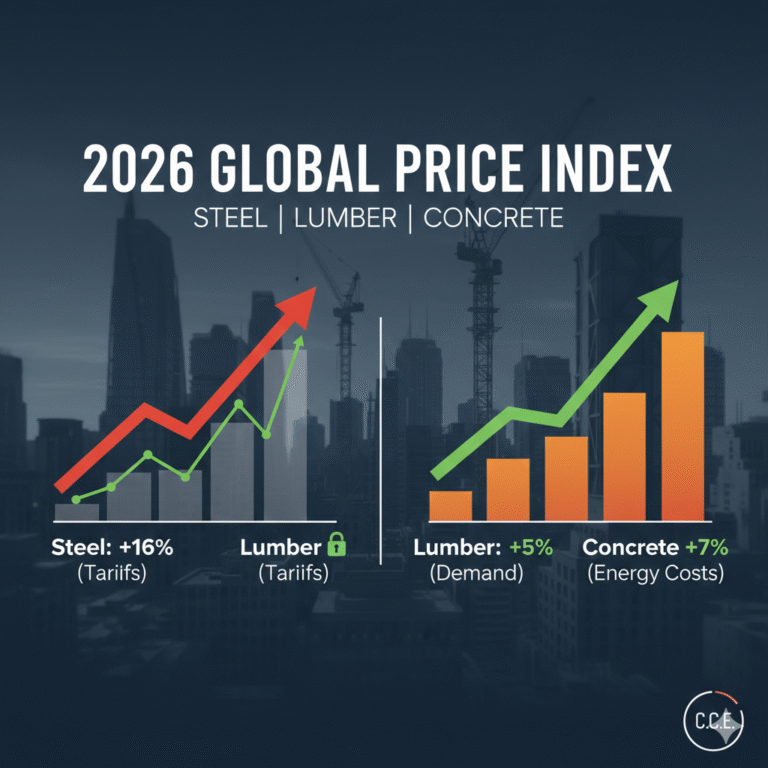

Estimators must consider factors such as fluctuating material prices, regional labor shortages, and project-specific risks like environmental compliance. In heavy industrial projects, delays can cost millions per day. Without accurate planning, disputes between owners and contractors can escalate quickly, leading to financial losses for all parties.

Professional industrial estimating services anticipate these challenges, building contingencies into estimates and offering clear, data-backed insights that reduce uncertainty.

Why Choose U.S.-Based Industrial Estimating Services

Choosing a professional firm for industrial estimating services USA gives contractors and owners several advantages. Local estimators understand regional labor markets, material pricing trends, and compliance requirements. They also have the ability to integrate estimates into full project management workflows, linking costs to schedules and procurement plans.

For EPC contractors, outsourcing to a specialized estimating firm provides flexibility. Instead of maintaining a large in-house estimating team, they can scale resources as needed, ensuring consistent quality without additional overhead. This not only reduces costs but also strengthens competitiveness in the U.S. industrial construction sector.

Conclusion – Accuracy That Builds Confidence

Industrial projects are too large, too complex, and too costly to rely on guesswork. Whether it is a manufacturing facility estimate, electrical estimating for industrial buildings, or a high-pressure industrial shutdown project estimation, success depends on reliable cost planning.

By working with expert firms that provide industrial estimating services, contractors and project owners gain access to accurate, transparent, and realistic estimates that reduce risk and increase profitability. When integrated with construction estimating services for precise project planning, industrial estimates provide the foundation for stronger bids, smoother execution, and successful project delivery.

In an industry where millions of dollars are on the line, precise industrial estimating is not just a support service—it is the cornerstone of trust, control, and long-term success.

FAQs on Industrial Estimating Services

What do industrial estimating services include?

They cover detailed cost analysis for materials, labor, equipment, and specialized systems such as MEP and electrical installations. Estimators also prepare schedules, waste allowances, and subcontractor evaluations.

How are industrial estimates different from residential or commercial estimates?

Residential and commercial projects deal with smaller scopes like finishes and basic utilities, while industrial estimating involves heavy equipment, process systems, and complex safety compliance, requiring specialized expertise.

Can industrial shutdown project estimation save costs?

Yes. Proper shutdown estimation reduces downtime, ensuring maintenance and upgrades are completed efficiently. This minimizes lost revenue and avoids unplanned expenses.

Which software is commonly used for industrial construction estimating?

PlanSwift, Bluebeam Revu, and RSMeans are widely used. However, the final accuracy depends on the estimator’s field knowledge and experience, not just the software.

Why should contractors outsource industrial estimating services?

Outsourcing saves overhead, provides access to expert estimators familiar with U.S. codes, and ensures reliable bid preparation. It also allows contractors to scale resources according to project size.