On-site, the difference between a profitable project and a costly failure often comes down to the quality of your takeoff. For example, we’ve seen estimators assume slab quantities from floor plans without verifying embedded steel or insulation layers only to discover a $25,000 discrepancy in concrete orders during pouring. Builders who skip detailed lumber or MEP takeoffs face last-minute change orders that delay schedules by weeks and inflate labor costs.

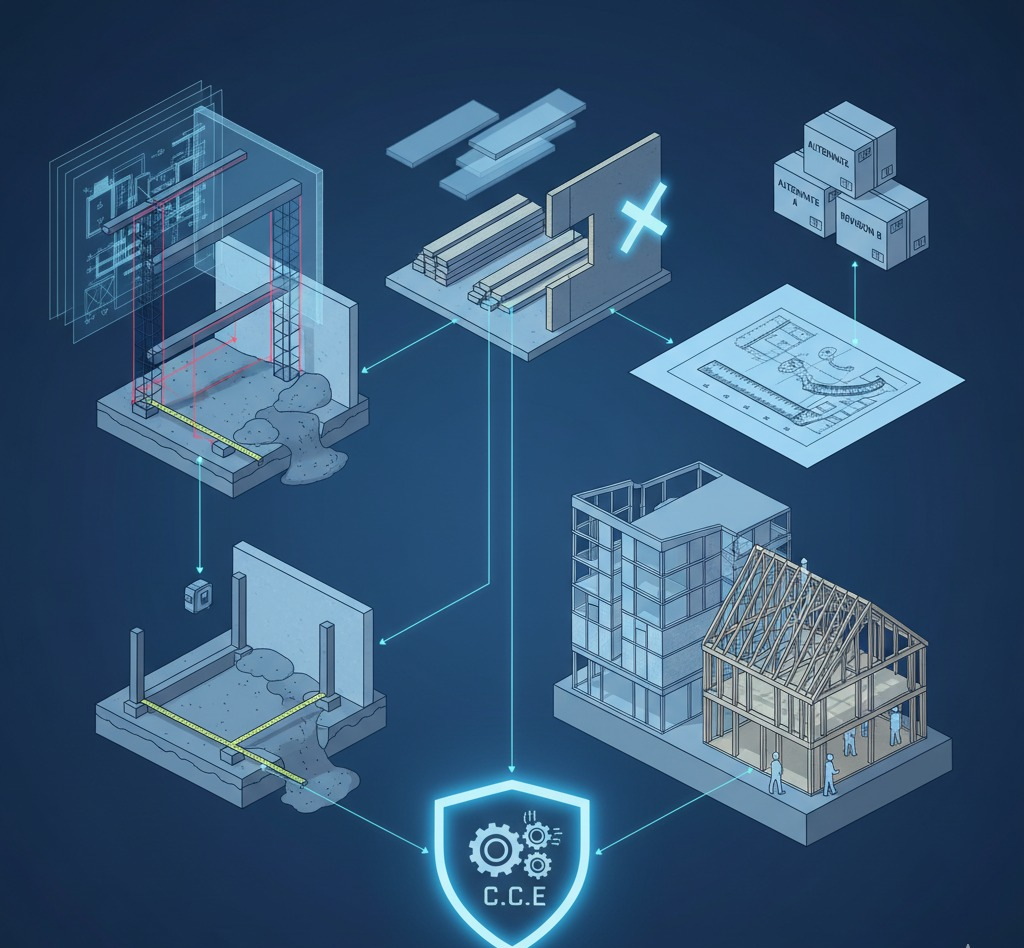

At Construction Cost Estimation Service (C.C.E), we approach every project with precision, field insight, and layered verification. Each takeoff is treated not as a checklist, but as a risk-mitigation tool capturing hidden materials, complex assemblies, and site-specific conditions that generic takeoffs often miss. When we deliver your takeoff, it’s not just numbers; it’s a strategic blueprint for cost certainty and bid confidence.

To give you a clear, measurable quantity breakdown that protects your bid, your budget, and your reputation.

The construction takeoff is much more than counting materials; it is the process of extracting every measurable component from your drawings materials, quantities, areas, lengths, counts, and assemblies and organizing them into a format that can be accurately priced and used for reliable bidding. Think of a takeoff as a map for your construction project: if the map is wrong, every subsequent decision, from procurement to labor planning, can become costly.

C.C.E approaches every takeoff with field experience, layered verification, and practical insight, ensuring no hidden materials or assemblies are missed. Each takeoff serves as a risk mitigation tool, aligning your project scope, schedule, and budget with real-world construction conditions.

Accurate takeoffs are not just about counting materials they require structured organization and intelligent modeling. This is where CSI (Construction Specifications Institute) standards and BIM (Building Information Modeling) play a critical role.

C.C.E integrates CSI and BIM practices to ensure your takeoff is traceable, standardized, and highly precise, reducing risk and enabling confident bidding.

CSI Division | Purpose in Takeoff | Expert Insight / Impact |

01 – General Requirements | Covers project management, quality control, temporary facilities | Ensures administrative and general costs are accurately accounted for |

02 – Existing Conditions | Site prep, demolition, environmental remediation | Avoids surprise costs from existing conditions |

03 – Concrete | Foundations, slabs, structural concrete | Accurate volume, reinforcement, and formwork quantities |

04 – Masonry | Block, brick, stone | Correct units, mortar, and structural integration |

05 – Metals | Structural steel, metal framing | Exact member counts and connection hardware |

06 – Wood & Plastics | Lumber, engineered wood, composite panels | Prevents shortages in framing and finishes |

07 – Thermal & Moisture Protection | Insulation, roofing, waterproofing | Ensures assemblies meet design and code |

08 – Doors & Windows | Frames, hardware, glazing | Eliminates last-minute field adjustments |

09 – Finishes | Flooring, ceilings, wall finishes, paint | Ensures accurate coverage and material ordering |

10 – Specialties | Signage, fire protection, equipment | Captures all specialty items that often get overlooked |

Organizing your takeoff by CSI divisions makes it standardized, auditable, and easier to hand over to subs or clients, while reducing errors that occur when estimating across mixed or unstructured plans.

Building Information Modeling (BIM) allows estimators to extract quantities directly from a 3D model, capturing hidden layers, assemblies, and spatial relationships that 2D plans can’t reveal.

BIM Feature | Purpose in Takeoff | Benefit to Estimator / Contractor |

3D Geometry | Captures full assemblies: walls, roofs, slabs, MEP | Reduces miscounted or missed items |

Clash Detection | Highlights conflicts between trades | Prevents costly on-site rework |

Parametric QTO Verification | Quantities automatically reflect model changes | Ensures takeoffs are always up-to-date |

Material Layers | Differentiates insulation, finishes, structural elements | Accurate BOM (Bill of Materials) for procurement |

5D Cost Integration | Links quantities to pricing | Immediate cost modeling for bids |

Visualization | Realistic view of design | Confirms constructability before ordering |

Version Tracking | Tracks model revisions | Avoids errors from outdated drawings |

While software like Revit or ArchiCAD helps, the real value comes from estimators who interpret the model checking implied materials, assemblies, and field realities ensuring fully defensible takeoffs.

C.C.E integrates CSI standards with BIM modeling to produce takeoffs that are:

Benefit | Practical Example |

Standardized & Traceable | Every quantity linked to a CSI division |

Error Reduction | BIM identifies missing or misaligned assemblies before bidding |

Time Efficiency | Automated extraction of quantities from 3D models |

Cost Confidence | 5D integration ensures accurate pricing of materials, labor, and assemblies |

Enhanced Collaboration | Easy handover to contractors, subs, and owners with clear documentation |

Using CSI and BIM together, C.C.E provides takeoffs that are precise, auditable, and construction-ready. Estimators can confidently submit bids, knowing nothing is left uncounted, hidden, or misrepresented.

Takeoff Component | Purpose / Expert Insight | Impact if Missed |

Drywall (Square Feet) | Measures all walls and ceilings, including multiple layers, niches, and bulkheads. | Underestimation leads to shortages, rework, and wasted labor. |

Concrete (Cubic Yards) | Calculates footings, slabs, walls, and foundations with embedded steel and insulation layers considered. | Wrong assumptions can cause over-pouring, material waste, and cost overruns. |

Rebar / Reinforcement | Quantifies steel requirements per design specs, including embedded elements and cut allowances. | Missing quantities delay structural work and increase procurement costs. |

Doors, Windows, Fixtures | Counts and tracks openings, hardware, and MEP fixtures as per drawings. | Miscounts lead to field adjustments, last-minute ordering, and schedule delays. |

Lumber (Board Feet) | Measures framing, roof assemblies, floor joists, and headers with precise calculations. | Shortages or excesses impact framing schedule and budget; increases material waste. |

Labor Hours | Estimates required labor based on quantity, productivity, and site conditions. | Poor labor projections inflate cost, reduce profit, and cause schedule slippage. |

Assemblies | Captures complex layers: walls, floors, roof systems, partitions. | Ignoring hidden layers leads to incomplete bids and unexpected change orders. |

Overall Scope Verification | Ensures all sheets, details, and addenda are cross-referenced. | Incomplete takeoff creates risk of missed items, inaccurate cost estimates, and client disputes. |

Construction takeoff failures typically occur for one reason: Missing information during measurement.

Here are real, recurring mistakes we see contractors make (and how much they cost):

Mistake in Takeoff | Why It Happens | Real Impact on Contractor |

Missing structural elements behind architectural layers | Estimator relied only on the plan, ignored structural sheets | $15,000+ in rework + schedule delay |

Wrong concrete depth assumptions | Drawings not cross-checked with detail pages | 20%–30% concrete over-or-under calculation |

Lumber counts taken from schematic sheets | No layer separation or framing logic considered | Framers request additional change order mid-construction |

Missing waterproofing, insulation, vapor barrier | Hidden items in wall/roof assembly not visually measured | Failed inspection + $5,000–$25,000 extra materials |

Duplicate quantities taken from multiple sheets | Plans included alternates and revisions | Bid becomes uncompetitive or underpriced |

Misreading scale or using outdated drawings | No digital verification or sheet tracking | Incorrect QTO affecting entire BOQ |

Not separating commercial vs residential assemblies | Wrong production rate + wrong material type | Labor cost inflated by 40% |

Every example above is based on real field situations estimators deal with daily.

C.C.E prevents these failures by using layered measurement, sheet coordination, detail extraction, and assembly logic not guesswork.

Below is how C.C.E performs construction takeoff services in a professional, audited, and fully documented way:

Stage | What We Do | Why It Matters to You |

Drawing Intake | We study architectural, structural, MEP, civil, and addenda | Eliminates wrong scope; ensures full-sheet coverage |

Scope Definition | Confirm inclusions/exclusions with GC/Client | Prevents surprises or missed materials |

Digital Measurement | PlanSwift, Bluebeam, Revit, and Cubit tools | Ensures accuracy down to the inch |

Assembly Mapping | Connect materials to assemblies (e.g., wall types) | Avoids missing items hidden inside assemblies |

Quantity Verification | Cross-check between sheets, notes, details | Removes duplication or incorrect counts |

Takeoff Documentation | Organize quantities by CSI divisions | Your subs and vendors get clear pricing sheets |

Final Review & QC | Senior estimator re-verifies entire takeoff | Zero-risk quantities for bid or construction |

This workflow ensures every takeoff is accurate, traceable, and aligned with international estimating standards.

Material Category | What We Measure | Why It Matters |

Concrete | Footings, slabs, walls, beams | Prevents concrete shortage/overpour |

Masonry | CMU units, grout, rebar | Ensures accurate block counts |

Drywall | SF of walls, ceilings, layers | Perfect for estimating production |

Finishes | Tiles, paint, flooring | Accurately divides rooms & patterns |

Metals | Structural steel, angles, plates | Essential for fabrication pricing |

Roofing | Membrane, insulation, flashing | Ensures weatherproofing materials aren’t missed |

We calculate labor using production rates, crew compositions, construction type, and building size to ensure field-realistic labor hours not textbook formulas.

Assemblies include all required layers:

This ensures no material inside the assembly is forgotten.

Lumber Type | What’s Included |

Framing Lumber | Studs, plates, headers |

Sheathing | OSB, plywood |

Engineered Wood | LVL, PSL, Glulam |

Roof Framing | Joists, rafters, trusses |

Hardware | Clips, hangers, connectors |

C.C.E is widely used by builders who want precise lumber counts for new homes and multifamily projects.

C.C.E provides construction takeoff services across:

Region | Service Coverage | Common Project Types |

Michigan Construction Takeoff Services | Detroit, Grand Rapids, Ann Arbor | Schools, commercial plazas, residential |

Arizona Construction Takeoff Services | Phoenix, Tucson, Scottsdale | Hospitality, desert-climate builds |

UK Takeoff Services | England, Scotland, Wales | Housing, mid-rise, retail |

Canada Takeoff Services | Ontario, Alberta, British Columbia | Mixed-use, industrial, infrastructure |

Our workflow adapts to local codes, climate conditions, and material specifications.

Our expertise covers:

Construction Type | How C.C.E Supports You |

Commercial Estimating | High-rise offices, hotels, schools, retail complexes → Detailed breakdowns with assemblies and MEP clarity. Commercial Estimating Service) |

Residential Estimating | Single-family, multifamily, townhomes → Lumber, concrete, framing, finishes takeoff. Residential Estimating Services) |

We tailor each takeoff to project type no generic templates.

We use industry-leading software for precision:

Software | Purpose |

PlanSwift | Fast digital takeoff & assemblies |

Bluebeam Revu | Detailed markups, PDF scaling |

Revit | 3D model–based measurement |

Cubit | Complex quantity modeling |

On-Screen Takeoff | Large commercial projects |

Software alone is not enough.

The experience of the estimator is what makes takeoffs accurate; the tools only enhance their judgment.

Decision Factor | What to Look For | Why It Matters |

Accuracy | Layer-based measurement | Prevents change orders |

Experience | Estimators with field background | Realistic quantities |

Deliverables | CSI-division sheets | Easy vendor pricing |

Turnaround | 24–48 hours | Faster bidding |

Transparency | Clearly marked drawings | Easy verification |

Support | Clarification availability | Zero confusion in bids |

Choosing C.C.E guarantees you are working with professional estimators, not automated algorithms.

Industry | Example Projects |

Hospitality | Hotels, motels, resorts |

Healthcare | Hospitals, clinics, urgent care |

Education | Schools, colleges, training centers |

Retail | Shopping malls, commercial plazas |

Industrial | Warehouses, logistics hubs |

Transportation | Airports, subway systems |

Real Estate | Condominiums, apartments |

Public Infrastructure | Libraries, civic buildings |

We adapt each estimate to the unique cost logic of that industry.

Home and building takeoffs require a different level of detail compared to typical commercial projects. C.C.E identifies:

Home Type | What We Evaluate |

Single-Family Homes | Lumber, slabs, roofing, finishes |

Two-Story Houses | Floor systems, stair assemblies |

Multifamily Buildings | Repetitive unit assemblies |

Custom Homes | Specialty materials and custom fixtures |

Commercial Buildings | Steel, concrete, MEP, façade systems |

We look at the home or building as a complete system, not isolated parts.

Takeoff alone means nothing without cost structure.

Our integration includes:

Layer | Purpose |

Quantity Extraction | Base measurement |

Cost Modeling | Material + labor costing |

Rate Validation | Market pricing |

Final Estimate | Bid-ready document |

This creates a seamless transition from measurement to costing.

A construction takeoff is the complete breakdown of materials, quantities, and assemblies extracted from your project drawings. It is essential because the takeoff determines the accuracy of your bid, prevents scope gaps, and ensures that the contractor orders the right amount of material without shortages or waste. A poor takeoff leads to costly change orders, delays, and budget overruns.

C.C.E uses a combination of digital tools (PlanSwift, Bluebeam, Revit) and human expertise. Every takeoff goes through layered measurement, sheet-to-sheet verification, assembly mapping, and a senior QC review. This eliminates duplicated items, missing materials, or incorrect scaling and ensures every quantity is defensible.

A takeoff is the measurement stage — counting materials and quantities. An estimate converts those quantities into cost using labor rates, material prices, equipment, and markups. C.C.E provides both services and also offers Residential Estimating Services and Commercial Estimating Service for complete bid packages.

Yes. We offer tailored solutions for Michigan, Arizona, UK, and Canada with material adjustments based on local standards, climate requirements, and regional pricing structures.

Standard projects are delivered within 24–48 hours. Complex commercial buildings may require additional time for detailed assemblies.

Yes. Lumber takeoff is one of our specialties. We provide framing counts, sheathing, roof framing, joists, headers, and hardware quantities in board feet.

Absolutely. We track revisions, clouded changes, and addenda to ensure the final takeoff reflects the most current design — preventing outdated or incorrect measurements.

We use PlanSwift, Bluebeam, Cubit, Revit, and On-Screen Takeoff. However, the true value comes from our experienced estimators who understand how buildings are constructed.

Yes. Our takeoffs support drywall contractors, concrete contractors, framers, MEP subs, roofers, masons, general contractors, developers, and owners across the USA, UK, and Canada.

Choose a provider with field-experienced estimators, transparent deliverables, layered measurement, CSI-aligned formats, and a QC process. Avoid automated software-only companies. C.C.E meets all professional standards required by commercial and residential contractors.

OUR SERVICES

Contact us today to get started on your construction projects and experience the difference of working with Construct Estimates.

Get notified about new articles