Most construction projects do not fail because of concrete or steel. They fail because mechanical, electrical, and plumbing costs were guessed instead of calculated. MEP systems carry the highest coordination risk and some of the highest per‑square‑foot costs in any building. If your MEP estimate is even slightly off, budgets collapse, bids become uncompetitive, and change orders start early.

At Construction Cost Estimation Service (C.C.E), our MEP estimating services are built for real-world construction. We do not rely on generic averages. We measure, quantify, and price every system based on drawings, specifications, local codes, and current market pricing across the USA, UK, and Canada.

To give you a clear, measurable quantity breakdown that protects your bid, your budget, and your reputation.

MEP estimating is the process of breaking down mechanical, electrical, and plumbing systems into measurable, priceable components. A proper MEP estimate answers practical questions contractors and owners actually care about. It tells you how much HVAC equipment is required, how many fixtures and outlets exist, how much piping and conduit is needed, and what the real labor demand looks like.

A professional MEP estimator does more than count symbols. They interpret design intent, identify scope gaps, and align drawings with specifications so nothing important is missed. This is why experienced MEP estimating reduces disputes later in construction.

Many MEP estimates fail because they are rushed or handled by people without field understanding. Generic assemblies, outdated pricing, and missed coordination between trades create gaps that only appear once construction begins. By then, the damage is already done.

We often review projects where ductwork conflicts with structure, electrical loads are underestimated, or plumbing fixture counts do not match code requirements. These are not design problems. They are estimating and coordination problems.

We follow a structured workflow that mirrors how MEP systems are actually installed in the field.

Step | What We Do | Why It Matters |

Drawing Review | Study plans, specs, schedules, and addenda | Prevents scope gaps and missed systems |

Trade Separation | Split mechanical, electrical, and plumbing clearly | Avoids overlap and double counting |

Quantity Takeoff | Measure ducts, pipes, conduits, fixtures, equipment | Forms the backbone of accurate pricing |

Labor Analysis | Apply realistic production rates | Prevents labor overruns |

Cost Pricing | Use regional material and labor data | Keeps bids competitive |

Final Review | Cross-check with code and scope | Reduces RFIs and change orders |

This process allows our mep estimating services to support clean bids and predictable construction costs.

Mechanical systems usually represent the largest portion of MEP cost. We quantify HVAC equipment, ductwork, insulation, controls, and accessories with attention to layout complexity and ceiling conditions. Our experience with cost‑efficient MEP design practices for residential development projects allows us to flag overdesigned systems before they inflate budgets.

Contractors rely on these numbers to plan procurement and installation sequencing. Owners use them to understand how design choices affect long-term operating cost.

Electrical estimating is not just counting outlets. We analyze lighting layouts, panel schedules, feeders, branch circuits, grounding, and special systems. When clients ask what an MEP cost estimator does, this level of detail is the answer.

For projects that require electrical scope support, we naturally coordinate with our Electrical Estimating Services so power loads and distribution align correctly across trades.

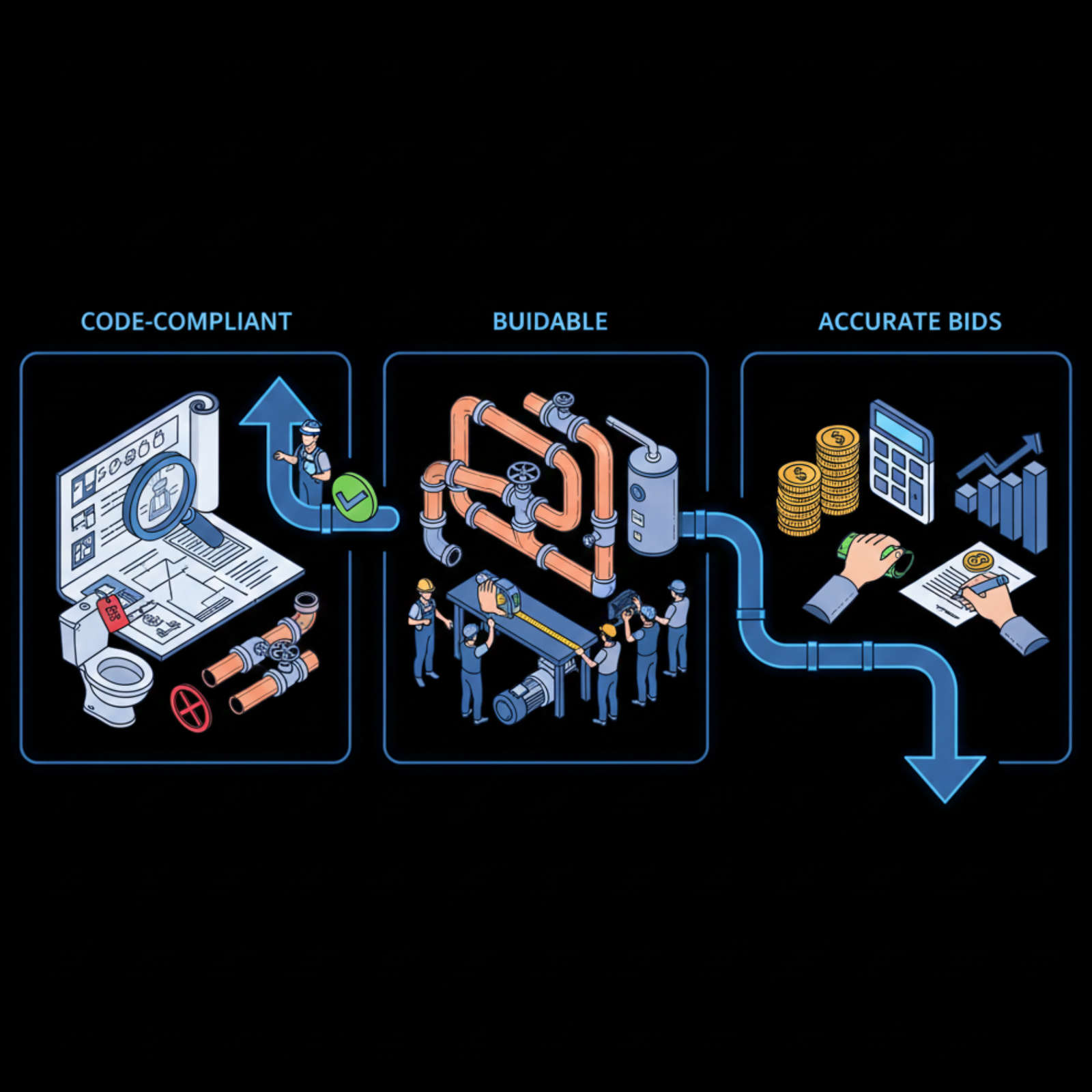

Plumbing estimates must satisfy code, pressure requirements, and fixture counts while remaining buildable. We measure domestic water, sanitary, storm, gas piping, fixtures, and specialties with attention to routing and vertical coordination.

This approach reduces conflicts during rough‑in and keeps inspection approvals smoother.

Many clients ask how much does MEP cost per square foot. The honest answer is that it depends on building type, system complexity, and local labor rates. Still, estimates help establish realistic expectations.

Building Type | Typical MEP Cost Range (USD/SF) | Cost Drivers |

Residential | $18 – $35 | HVAC type, fixture count |

Commercial | $25 – $55 | Lighting density, controls |

Healthcare | $45 – $90 | Redundancy, air changes |

Education | $30 – $60 | Code compliance, capacity |

These ranges guide early decisions but are refined through detailed MEP estimating.

Many contractors use Viewpoint MEP estimating and need help getting accurate results from the software. We support workflows such as how to do a takeoff with Viewpoint MEP estimating and how to get started with Viewpoint or Viewport MEP estimating.

We also assist with tasks like printing to PDF with Viewpoint MEP estimating and aligning takeoffs with cost databases. Software does not replace expertise, but when used correctly, it improves efficiency.

Questions like how much AutoCAD MEP students cost or how much CAD MEP fabrication costs often come up during preconstruction. While software licensing is separate from estimating, we understand how fabrication-level detail impacts labor and material pricing.

This awareness helps align design detail with budget reality.

We provide Florida MEP estimation support as well as projects across the USA, UK, and Canada. We also work with international clients, including coordination related to MEP Costa Rica projects where scope alignment with North American standards is required.

Local code knowledge and labor productivity differences are always reflected in our estimates.

Clients often look for cost-saving strategies from leading MEP design firms or top‑rated MEP cost optimization experts in the US. True optimization comes from understanding where money is being spent, not blindly reducing scope.

We highlight alternate materials, routing efficiencies, and system sizing adjustments that reduce cost without compromising performance. This approach supports schools, residential developments, and commercial facilities seeking cost‑effective MEP design services.

Residential projects focus on efficiency, repetition, and lifecycle cost. Commercial projects require coordination, redundancy, and higher system loads. Our MEP estimating adapts to both without forcing one model onto the other.

This flexibility is why contractors return to us across different project types.

MEP estimating services cover the full cost analysis of mechanical, electrical, and plumbing systems before construction starts. This includes quantity takeoffs, labor calculations, equipment pricing, and coordination checks between HVAC, electrical distribution, and plumbing layouts. A proper MEP estimate also accounts for installation complexity, access issues, and local code requirements. At C.C.E, our MEP estimating services are built to support accurate bidding, budgeting, and construction planning for projects across the US, UK, and Canada.

An MEP cost estimator reviews drawings, specifications, and design intent to convert system layouts into measurable costs. This includes calculating ductwork lengths, pipe sizes, electrical loads, panel counts, fixtures, and equipment capacities. The estimator also evaluates how systems interact, because clashes between trades are one of the biggest cost risks in MEP work. Our MEP estimator team focuses on preventing scope gaps that usually show up later as change orders.

MEP cost per square foot depends heavily on building type, system complexity, and performance requirements. A residential project with basic HVAC and electrical layouts will cost significantly less than a hospital, school, or commercial building with advanced controls and redundancy. Our MEP estimating process breaks costs down by system so owners and contractors can see exactly where money is being spent and where cost-saving strategies can be applied without hurting performance.

Residential MEP estimating focuses on repeatable layouts, smaller system capacities, and simplified coordination. Commercial and institutional projects require much deeper analysis of electrical load estimation for buildings, HVAC zoning, plumbing demand, and life-safety systems. At C.C.E, we adjust our MEP estimating approach based on whether the project is residential, mixed-use, educational, healthcare, or industrial, so the estimate matches real construction conditions.

Yes. Many clients use our estimates to test cost-efficient MEP design practices for residential development projects and commercial buildings. By comparing alternative layouts, equipment selections, and routing options, we help teams understand which design decisions increase installation cost and which ones actually save money. This approach is often used during value engineering and early budgeting stages.

Yes, we regularly support contractors using Viewpoint MEP estimating. We help with takeoffs, system quantities, and structured data that can be imported or cross-checked within Viewpoint workflows. Clients often ask how to do a takeoff with Viewpoint MEP estimating or how to get started with Viewpoint MEP estimating, and our estimates are built to align cleanly with those systems for smoother project setup.

Accuracy comes from understanding both design intent and real installation conditions. We calculate estimated electrical loads for buildings based on code requirements, equipment demand, and future capacity allowances. HVAC estimates include system sizing, duct routing, insulation, and controls. This level of detail helps prevent underestimating costs that typically surface during coordination or inspection phases.

Yes. We regularly provide MEP estimating services for schools, universities, and public facilities. These projects require careful attention to code compliance, durability, energy efficiency, and long-term operating costs. Many clients come to us looking for where to find cost-effective MEP design services for schools, and our estimates are structured to support funding approvals and public-sector bidding requirements.

Our role is not just to total numbers but to explain them. We support cost-saving strategies from leading MEP design firms by clearly showing how changes in layout, material selection, or system type affect the overall budget. This allows owners and contractors to make informed decisions instead of cutting scope blindly and risking performance issues later.

MEP estimating is closely tied to detailed electrical takeoffs and pricing. For projects that need deeper electrical analysis, we coordinate directly with our Electrical Estimating Services to ensure consistency between system-level budgets and trade-level estimates. This avoids mismatches between overall MEP numbers and detailed electrical bids later in the process.

OUR SERVICES

Contact us today to get started on your construction projects and experience the difference of working with Construct Estimates.

Get notified about new articles